Mature companies are used to outsourcing parts of their business that grow the top line:

- PR for increased awareness

- Ad agencies to manage paid media efforts

- Creative shops for graphic design and video production

- Digital groups for website management, SEO, and more

Operations, though, are almost always kept internal.

And for good reason. Who knows how to do “the work” than the business itself?

Yet, there is a difference between doing the work (building the product, serving the client, delivering the food, etc.) and facilitating the work.

As COO, one of the biggest challenges I saw at my previous company is the work that happens between departments. The connective tissue. The inner-workings.

Coordinating work between teams or departments is hard but critical. The best companies in the world know it, and they optimize those pathways relentlessly. They looks for ways to reduce friction. The spot bottlenecks. They shrink the time it takes to generate value for their customers.

But eventually, companies reach stasis. Good becomes good enough.

In my experience, there are three main reasons operational teams get stuck:

- Swim Lanes

- Existing Processes

- Knowledge Gaps

#1: Swim Lanes

One major factor that hinders operational efficiency is the presence of rigid swim lanes within an organization.

Swim lanes refer to the boundaries and divisions that exist between different departments or functions.

Early on in a company’s lifecycle while teams are small, things are fluid. Everyone jumps on every problem. This agility encourages fast, collaborative problem solving – even if it comes at the expense of “efficiency.”

As a company matures, though, specific roles and responsibilities begin to form. Teams become more focused in their duties. While deep focus can be an advantage, groups that keep the blinders a little too tight miss opportunities for collaboration and improvement.

When teams focus exclusively on their swim lanes, communication and collaboration suffer. A sense of “that’s not my job” ultimately leads to bottlenecks and delays.

How to Break Down Swim Lanes

Foster Cross-Functional Collaboration

First, encourage teams to collaborate across swim lanes by organizing regular interdepartmental meetings or creating collaborative projects. Most employees don’t even realize there’s a problem until they talk to their peers or have an outside party view things from a new perspective. Meetings can enhance communication and improve problem-solving abilities by leveraging knowledge from various perspectives.

Implement Agile Methodologies

Try practices such as Scrum or Kanban that promote iterative and cross-functional work.

This may sound daunting, but we actually ran 2-week “Ops Sprints” (which I’ll write about in a future post) and they worked wonders.

These methodologies encourage collaboration, adaptability, and shared ownership, helping break down the barriers between teams.

Establish Clear Expectations

Improvement is everyone’s job, not just the owner or COO. Set clear goals and expectations for each individual and team, emphasizing the importance of cross-functional cooperation. By explicitly stating that success is dependent on collective efforts, teams will be more motivated to collaborate and support one another.

#2: Existing Processes

As an organization grows, it defines and builds its processes. At first, those processes are malleable. People do the best they can with the resources they have and make decisions with whatever information is available at that time – no matter how incomplete or incorrect it may be.

Over time, they mature and solidify. The once malleable processes become “good enough” to satisfy the project or the customer’s needs. Then, teams move on to the next fire.

While processes are crucial for maintaining consistency and standardization, obsolete, overly complex, or outdated procedures can impede efficiency and hinder progress. “This is the way we’ve always done it” is an understandable, yet scary, phrase because it admits no one has ever asked the question, “Can this be done better?” recently.

Can this be done better?

How to Improve Existing Processes

Process Review and Simplification

Conduct regular audits of existing processes to identify inefficiencies or bottlenecks. Streamline and simplify your processes wherever possible, and eliminate unnecessary steps or outdated requirements.

Encourage Continuous Improvement

Foster a culture of continuous improvement within the organization. Rather than “set it and forget it,” encourage employees to identify and suggest ways to enhance processes regularly. By empowering everyone to contribute, you tap into the collective wisdom of the team and drive ongoing optimization.

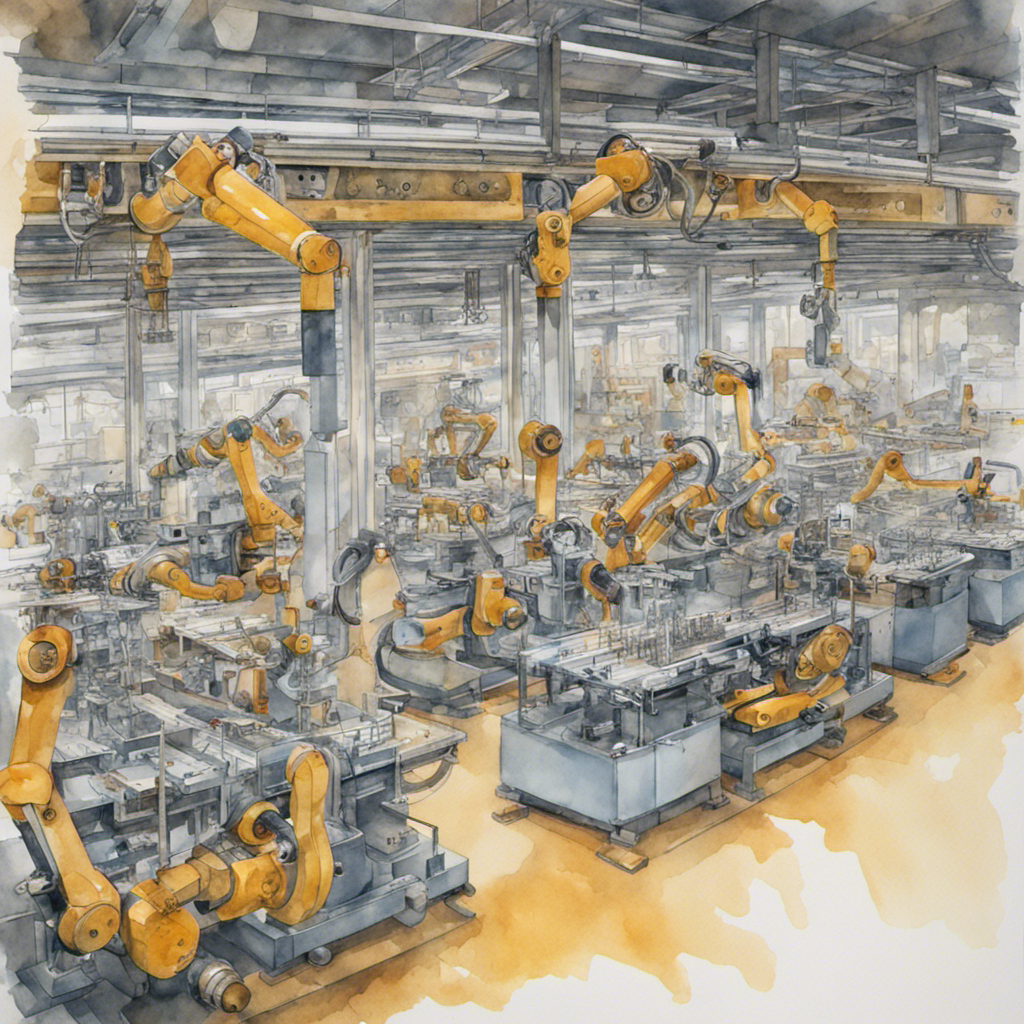

Embrace Automation and Technology

It is incredible how much new, mind-blowing technology is developed every year. Keeping up can be a full-time job, but leveraging technology and automation tools to optimize and streamline processes. Implementing software systems, workflow automation, or robotic process automation (RPA) can significantly reduce manual effort and improve operational efficiency when done well.

#3: Knowledge Gaps

I know Lionel Messi is an incredible soccer player. I even know what skills make him great. But that doesn’t mean I can do what he can on the field? Definitely not.

Even when teams know they could be doing better, it’s hard to know how to make it happen.

The third roadblock that often hampers operations teams is knowledge gaps.

When team members lack a comprehensive understanding of the overall business’s operations, they may struggle to make informed decisions or coordinate effectively. Similarly, they may know something needs to improve but not have the skills, resources, or political pull within a company to make the change.

How to Eliminate Knowledge Gaps

Cross-Training

Encourage programs where team members from different departments spend time working with other teams. This will broaden their understanding of the entire operation, enhance collaboration, introduce them to new skills that they could use on their own.

Shared Documentation and Knowledge Sharing

Implement a centralized and easily accessible knowledge-sharing platform (intranet or wiki) where employees can access essential information, best practices, and documentation. This enables teams to stay informed, learn from one another, and teach others how to do certain aspects of their jobs.

Regular Communication and Updates

Establish regular communication channels such as team meetings, newsletters, Slack, or intranet updates to disseminate important information. Encourage open communication and the sharing of insights and updates to bridge knowledge gaps effectively.

Does it make sense to outsource operations?

Bringing in a partner for any part of your business comes with drawbacks and benefits.

Outsiders can come with deep area expertise. If they’re good at their craft, they are can get things done more quickly and add value at a fraction of the cost. If they’re not, they become another expense that actually slows things down.

At ScaleWell, we work quickly to analyze your operations, map out your business’s critical processes, make recommendations for improvement, then work with your teams to implement solutions that save them time and money.

Final Thoughts

By addressing these three common operational pitfalls – swim lanes, existing processes, and knowledge gaps – organizations can get better results more profitably. Overcoming these challenges requires a combination of process improvements, technology adoption, building a culture of continuous learning and cooperation, and occasionally bringing in a trusted partner to implement their ideas for them.

Have your operational teams gotten stuck for reasons not listed above? If so, I’d love to hear about them below.